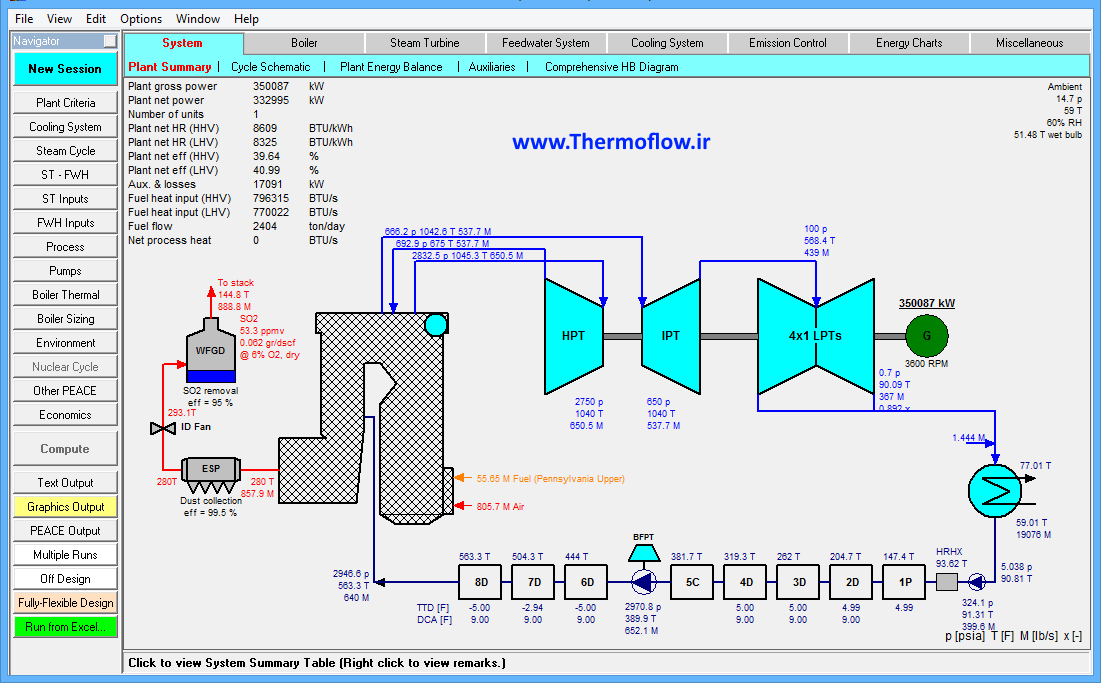

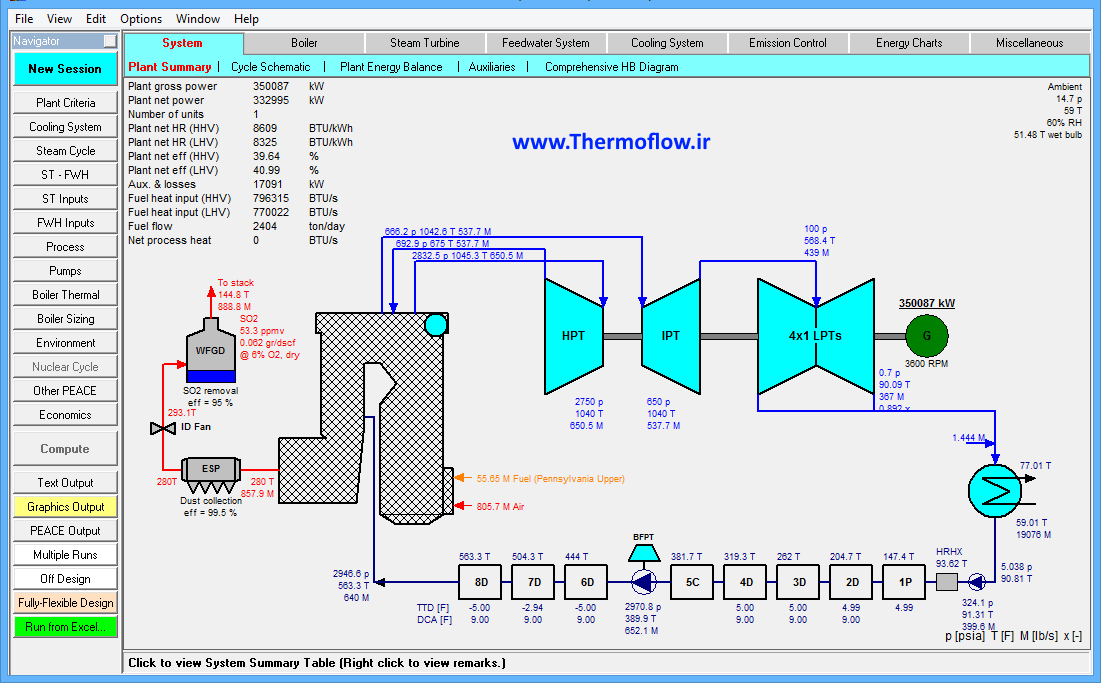

Thermoflo Equipment Company. Contact us today! 412-366-2012 OR 888-843-7661. About Us; News; Events. Steam Driven Condensate Return Units; Vacuum Return Packages. STEAM PRO® automates the process of designing a conventional (Rankine cycle) steam power plant, guiding the user to rapidly and easily attain an optimal configuration and its technical parameters.

- If you need help,please mail to us

- EMAIL:crackcad@gmail.com

- Skype:dwcrk.com

STEAM PRO and STEAM MASTER can now include a Flue Gas Cooler, recovering still more useful heat from the flue gas and delivering that heat to the feedwater heating system. THERMOFLEX now has a streamlined method for inserting and defining a Steam Turbine Assembly. Williamson-Thermoflo Co. Offers a full line of oil and gas furnaces, oil and gas boilers, indirect-fired water heaters, and air conditioning products. Williamson-Thermoflo is an independent business unit of Weil-McLain, which is a subsidiary of SPX Corp. SPX posted revenues of about $1.4 billion in 2017.

- Rank:

- Size:1CD

- Language:english

- Platform:Win7/WIN8

- Freshtime:2017-11-09

- Tag:Thermoflow 26 trainingThermoflow 26 tutorialsThermoflow 26 torrent

Thermoflow v26.0 Thermoflow is the leading developer of thermal engineering software for the power and cogeneration industries. Since 1987, Thermoflow's software product line has grown to become the most popular, well-proven, and comprehensive system available today. Thermoflow is a stable, profitable, entirely independent company which has never received funding from any source other than sales to customers who find real value in our products, every day. TEAM PRO automates the process of designing a conventional (Rankine cycle) steam power plant. It is particularly effective for creating new plant designs and finding their optimal configuration and design parameters. The user inputs design criteria and assumptions and the program computes heat and mass balance, system performance, and component sizing. The scope and level of detail in STEAM PRO has been continuously growing since 1990, to the point that the 2008 version has over 1800 user-adjustable inputs. Most key inputs are automatically created by intelligent design procedures that help the user identify the best design with minimal time and effort, while preserving the flexibility to make any changes or adjustments. STEAM PRO is truly easy to use, typically requiring only a few minutes to create a new plant design. It normally computes a heat balance and simultaneously designs the required equipment in under fifteen seconds. When run in conjunction with the optional PEACE module, the programs provide extensive engineering and cost estimation details. STEAM PRO allows you to quickly create steam plant design point heat balances, complete with outputs for plant hardware description, preliminary engineering details, and cost estimate with PEACE. The variety of steam plant configurations is virtually endless. From back pressure units with gas fired boilers without feedwater heaters, to oil-fired boilers feeding straight condensing turbines with a small number of heaters, to coal fired PC boilers, or CFBs feeding single reheat turbines with seven or eight heaters, to supercritical double reheat plants of the largest variety, each with any sort of cooling system, are all easily accommodated in STEAM PRO. GT PRO automates the process of designing a combined cycle or gas turbine cogeneration plant. GT PRO is particularly effective for creating new designs and finding their optimal configuration and design parameters. The user inputs design criteria and assumptions and the program computes heat and mass balance, system performance, and component sizing. The scope and level of detail in GT PRO has been continuously growing since 1988, to the point that the 2008 version has over 3000 user-adjustable inputs. Most key inputs are automatically created by intelligent design procedures that help the user identify the best design with minimal time and effort, while allowing the flexibility to make any changes or adjustments. GT PRO is truly easy to use, typically requiring only a few minutes to create a new plant design. It normally computes a heat balance and simultaneously designs the required equipment in under five seconds. When run in conjunction with the optional PEACE module, the programs provide extensive engineering and cost estimation details. GT PRO now includes a built-in, full-featured scripting language that allows you to add your own logical blocks to models. The GT Inlet Chilling/Heating Coil was augmented by addition of a full-featured hardware model of the coil. The new model includes full flexibility in design-point sizing and in engineering selection of materials and tube/fin geometry. THERMOFLEX+PEACE now includes a new comprehensive cost estimate for gas turbine plants, equivalent to what's available in GT PRO+PEACE. Outputs include a detailed overall cost report, cost report breakdowns showing all equipment, material, and labor, a site plan layout diagram, equipment data tables, and an investment report. A Solar PV component was added to THERMOFLEX. This icon models a photovoltaic array to provide estimate of current output power, annual power yield, field size and arrangement, and installed cost. A Wind Farm component was added to THERMOFLEX. This icon models one or more wind turbines and provides current output power, annual yield estimate, field arrangement, and installed wind farm cost. A Fired Boiler Assembly was added to THERMOFLEX. It provides a centralized set of output reports including a Specification detailing weights, dimensions and installed cost estimate, an ASME Heat Balance, Gas & Water data summaries, Plan & Elevation views, TQ diagram, etc. A Plate Heat Exchanger icon was added to THERMOFLEX. It computes heat transfer, heater geometry including plate details and overall weights and dimensions, and provides estimated heater equipment cost. The Gas Turbine Library was expanded to include additional engines and to revise performance and availability for some existing engine specs.

Previous:Mestrelab Research Mnova 12Next:Intergraph CADWorx 2018.v18.0.0_Plant Design

Thermoflow Steam Profile

Thermoflow Steam Products

- Contact Us

PERFORMANCE, PACKAGEDRelated BrandsCapping & Cap Handling Systems

Zalkin Bottle & Box Handles & Application Systems

Roberts PolyPro FILLING & CAPPING

FLEXIBLES

PRODUCT HANDLING

LABELING & CODING

END OF LINE

PHARMA

ProMach filling and capping solutions protect the quality, freshness, and flavor of products expected by your consumers - without compromising the productivity, reliability, and performance you need

Learn MoreProMach offers extensive experience handling a wide range of flexible packaging products in diverse conditions - many of the world's most successful brands are packaged by ProMach flexible solutions.

Learn MoreReposition and move products wherever you need it: ProMach designs and manufactures durable product handling solutions including conveyors, vision systems, retorts, loading systems, automation controls, and more

Learn MoreAccuracy, speed, and efficiency: ProMach is recognized across the globe as a leading, single-source supplier for high-quality labeling, coding, and marking systems for primary and secondary packaging.

Learn MoreFrom stand-alone applications to complete systems, manufacturers of every product type can reduce costs, optimize performance, and deliver more with ProMach integrated end-of-line solutions

Learn MoreMeet your most challenging pharmaceutical packaging requirements with minimal downtime, higher productivity, and true pharmaceutical packaging performance

Learn More